Getting My Motorcycle Parts New Zealand Specialists To Work

Table of Contents8 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Basic Principles Of Motorcycle Parts New Zealand Specialists Motorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Best Guide To Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?See This Report about Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsNot known Facts About Motorcycle Parts New Zealand Specialists

So, reach out to one of our experts today.CNC machining modern technology is promptly becoming the centerpiece of various production processes around the world as a straight outcome of its lots of benefits over other techniques. Furthermore, the markets that produce motorcycles have jumped on board with this fad. One of the most cutting-edge companies are currently establishing their engine parts and wheels utilizing machining methods initially created for motorbike components.

You might be wondering why we utilize. Now that we have your interest let us describe the reasoning behind this modern-day advancement in the motorbike production sector.

The Main Principles Of Motorcycle Parts New Zealand Specialists

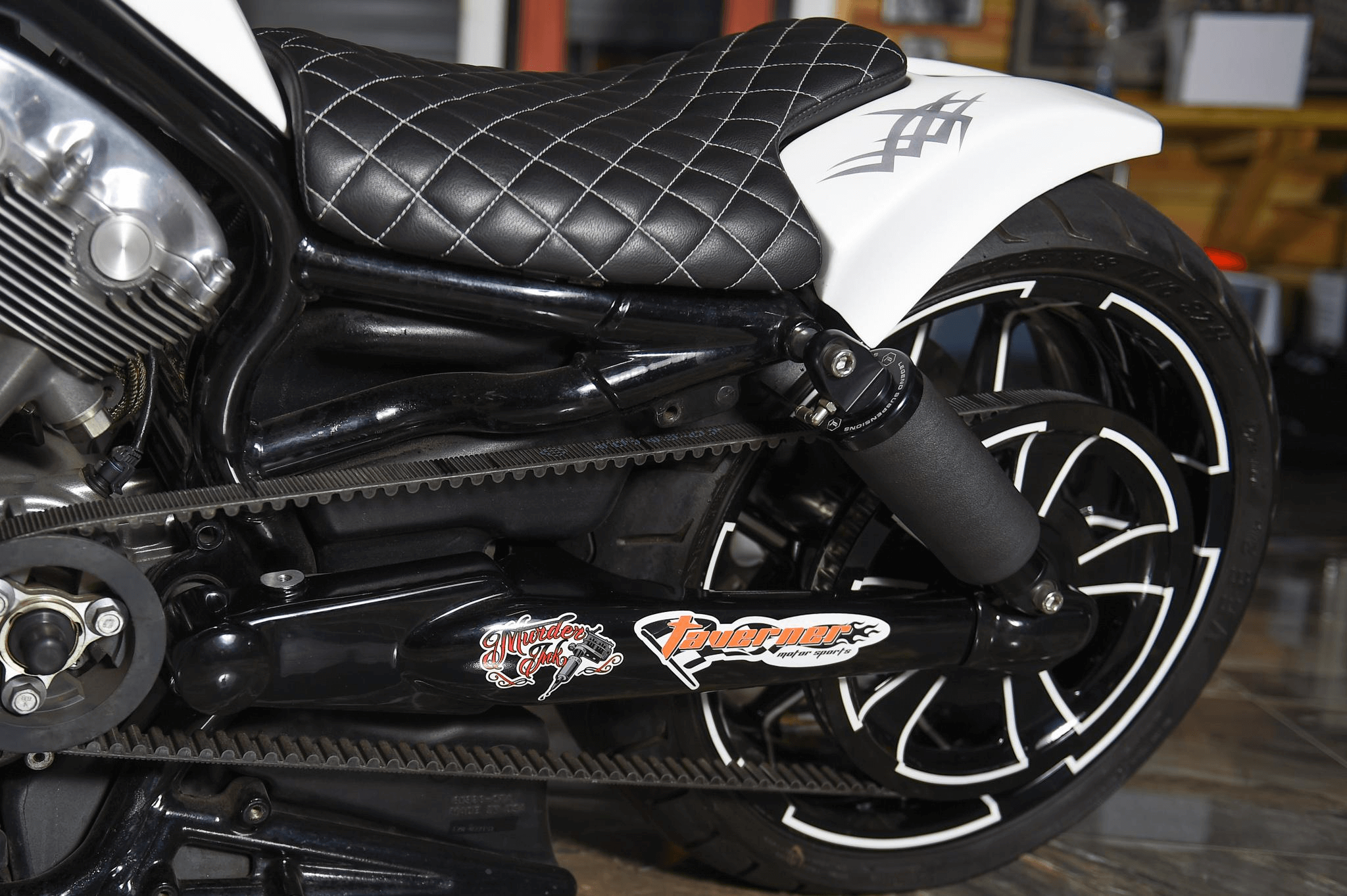

Additionally, you have complete control over the look of the components, even to the minute information. Periodically, motorcyclists may make a decision to spruce up their trip by setting up aftermarket elements or customizing the bike's remodeling. Once once again, computer system mathematical control (CNC) machining is one of the most sensible method. Upgrades may be of any type of form and design you desire.

Facts About Motorcycle Parts New Zealand Specialists Uncovered

CNC machining might be utilized to make nearly all of a motorbike's steel and plastic elements. To proceed, we'll review a number of machined parts for bikes. In comparison to those on autos, wheels on bikes have a tendency to be more evident. Because of this, the bike's looks may be enhanced with the proper modification of these wheels.

Milling procedures are utilized to obtain the desired degree of wheel modification. One more element of the motorbike that might be customized is the tires.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

When it involves a vehicle (or a motorcycle), one of the most crucial component is the engine. Numerous individuals suggest to it as the "heart" of the auto. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be complex and need designs with a high level of accuracy.

Use only high-grade products, however, since these lights are essential for the safety of motorcyclists and other chauffeurs or individuals on the roadway, specifically at night. Motorcycle fronts lights have three main parts: the light bulb, or light source, the lens, and the housing.

Milling processes with a perfect finish would cause the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the other hand, is not made up of vulnerable materials; instead, it is constructed out of difficult polymers that can be machined into even more elaborate patterns.

The Of Motorcycle Parts New Zealand Specialists

Motorbike manufacturers frequently cast these elements, yet only for the manufacturing of bespoke components. Machining on five axes in today's globe is the means by which any design form may be understood.

The success of the process is contingent on the mill cutters' ability to calculate refined and difficult angles accurately. Choose Runsom for your customized motorbike parts! We have the ability to fabricate complex and elegant elements making your bike matchless. A lot of are crafted from light weight aluminum or steel alloys, each of which has its usages and benefits.

Here are browse around these guys a couple of instances of steels typically utilized in motorcycle part machining. Aluminum is the primary product used by companies focusing on producing personalized bike elements to produce the majority of these parts. In the past, we would construct our engines out of cast iron. On the other hand, light weight aluminum is quickly becoming the material of option, partially because of the reality that it is more light-weight.

Zinc refers to an additional steel that is extremely light in weight and has wonderful machining high qualities due to its high mechanical strength. This material may be formed into nearly any type of form and keeps its measurements well. Even mission-critical components that require a high degree of precision may take advantage of their usage.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

Another metal that sees hefty usage in the manufacturing of CNC-customized parts is magnesium. It is among the lightest metals that are now easily accessible and has superb machinability features and toughness proportionate with its reduced weight. One of the disadvantages of magnesium is that its dust may quickly ignite.

As a result of its premium machinability and weldability, stainless-steel is an alloy that is specifically well-suited for CNC procedures. Along with this, they have wonderful corrosion resistance and a high visual charm. Their most typical usage in producing various motorcycle elements is bolts, such as screws and bolts. Their reduced vulnerability to oxidation and deterioration makes them perfect for this usage.

Fascination About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and grating are the foundational processes. In enhancement, it needs maintaining bars of product, most typically plastic or metal, in setting and after that twisting a reducing tool to get rid of sections of the product as the product is turned.

These techniques are equally important and generate elements with high accuracy and regular top quality. The processes help enhance the overall quality of the machined bike components.

The Definitive Guide for Motorcycle Parts New Zealand Specialists